WEISS Linear Units

WEISS North America’s Linear Units are available in various styles to include belt-driven, screw-driven and rod style actuators. Our products are extremely flexible and can be combined to provide automation solutions from the very simple to the complex. With a compact footprint, these solutions provide high performance features such as high speed, excellent accuracy and trustworthy repeatability.

Our decades of experience and leadership in mechatronics, process and supply chain management, along with world-class customer service and industry-specific expertise, have allowed us to grow and respond to all of our customers’ requirements. We are present and represented in all markets, precisely where our customers need us. WEISS North America is here to serve our customers as a one-stop-solution for automation in the United States, Canada and Mexico.

All of our Linear Units can be combined to develop multi-axis solutions. Standard and custom brackets, clamping fixtures, adapter plates and other accessories are also available.

We invite you to learn more about WEISS Linear Units below below.

BELT DRIVEN LINEAR UNITS

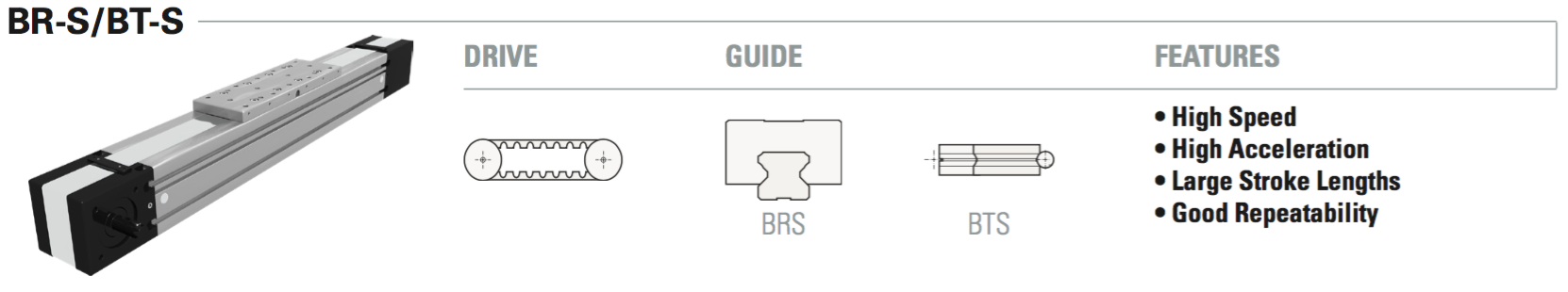

WEISS BR-S and BT-S Linear Units with toothed belt drive and compact dimensions provide high performance features such as, high speed, good accuracy and repeatability. They can easily be combined to multi-axis systems and offer excellent price/performance ratio with quick delivery times.

The compact, precision-extruded aluminum profile from 6063 AL with integrated zero-backlash ball rail guide system, allows high load capacities and optimal cycles for the movement of larger masses at high speed. For very high speeds, up to 10m/s, the track rollers (journal bearings) of the BT-S are particularly suitable.

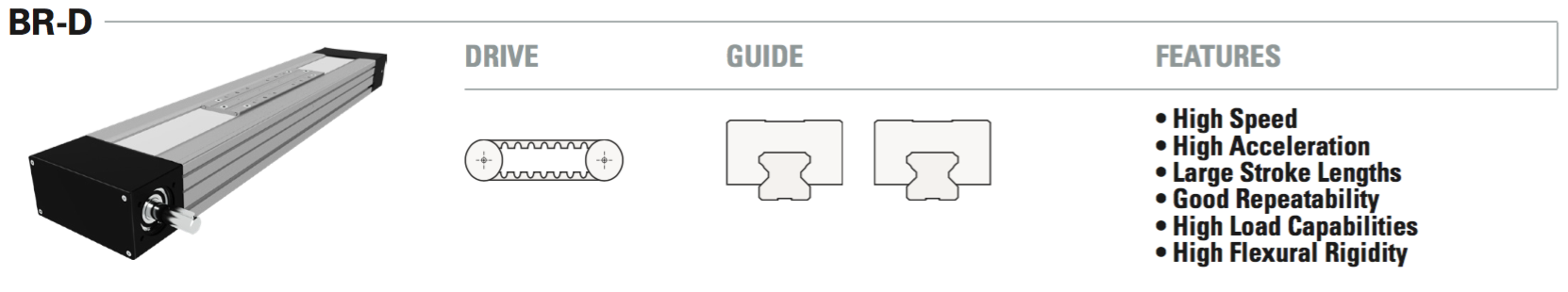

The WEISS BR-D series features linear units with a toothed belt drive and two parallel, integrated, zero-backlash rail guides. Compact dimensions allow high performance features such as, high speed and repeatability and can easily be combined into multi-axis systems. The BR-D series offers excellent price/performance ratio with quick delivery times.

Different carriage lengths with lubrication port allows for easy re-lubrication of the ball rail guide system and allows the possibility to attach additional accessories. The re-lubrication can also be done through maintenance holes on the side of the profile.

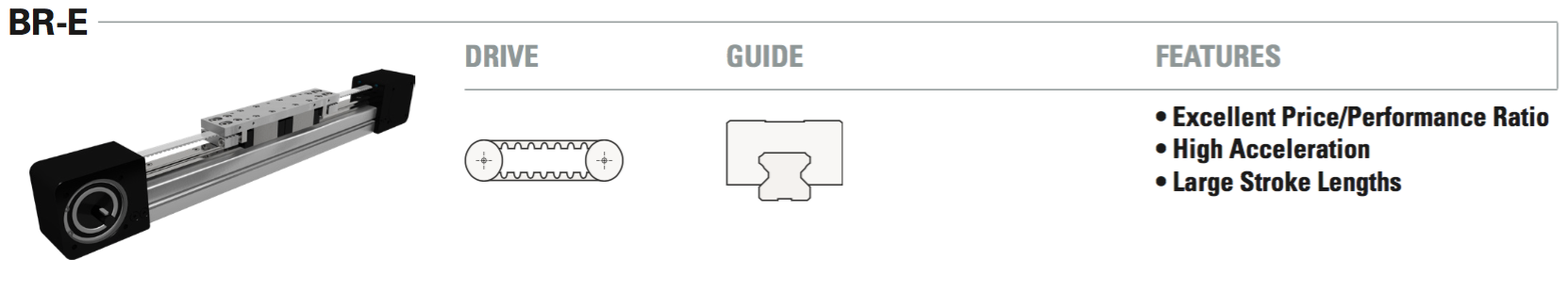

The WEISS BR-E series of linear units is a powerful and cost-effective solution with toothed belt drive and a zero-backlash ball rail guide system for easy and accurate linear movements. The BR-E series can also be easily combined to create multi-axis systems and offer an excellent price/performance ratio and quick delivery times.

The aluminum profile includes T-slots for fixing the linear unit and for attaching sensors and switches. Different carriage lengths of the linear unit allow the possibility to attach additional accessories on the side.

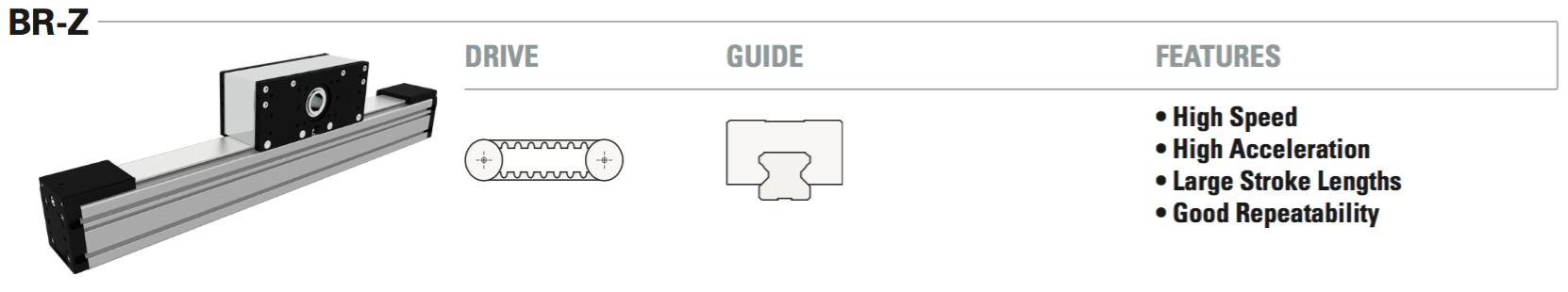

The WEISS BR-Z series contains z-axis linear units with toothed belt drive, integrated ball rail system and compact dimensions. This series of linear units provide high performance features such as, high speed, good accuracy and repeatability by vertical applications and can easily be combined to multi-axis systems.

The aluminum profile includes T-slots for attaching sensors and switches and a reed switch can also be used. The drive block provides the possibility to attach a motor or gearbox housing and additional accessories and the central lubrication port on the drive block allows easy re-lubrication of the ball rail guide.

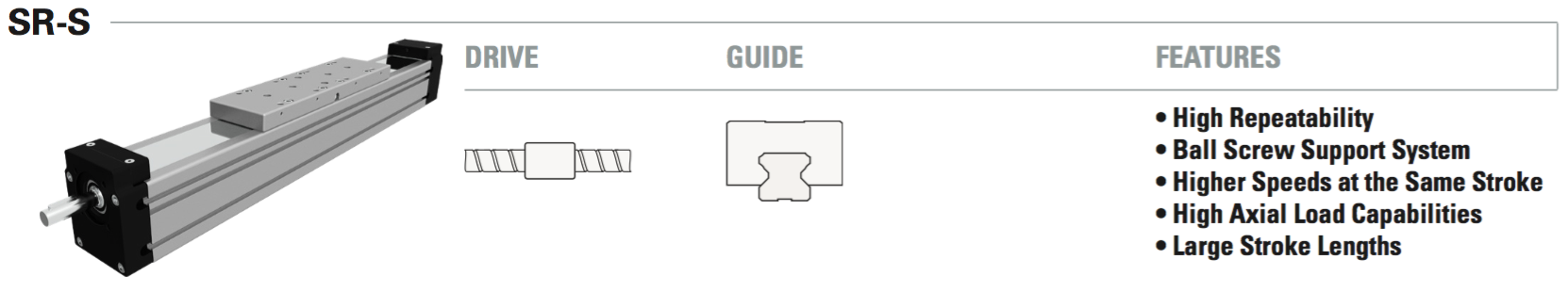

The WEISS SR-S series of linear units offer a precision ball screw drive, integrated guide rail and compact dimensions. These units come standard with a precision ball screw tolerance class of ISO7 (ISO5 available on request) with reduced backlash of the ball nut. The SR-S series provides high performance features, such as high speeds, good accuracy and repeatability and they can easily be combined to multi-axis systems.

To achieve higher speeds at the same stroke of the linear unit, our ball screw support system can be integrated. With this feature, vibrations and deflections of the ball screw are reduced, allowing for longer strokes. Our system enables ball screw support in horizontal or vertical positioning of the linear unit. A 2LR version of SR-S linear unit is also available, where two carriages are moving simultaneously in opposite directions.

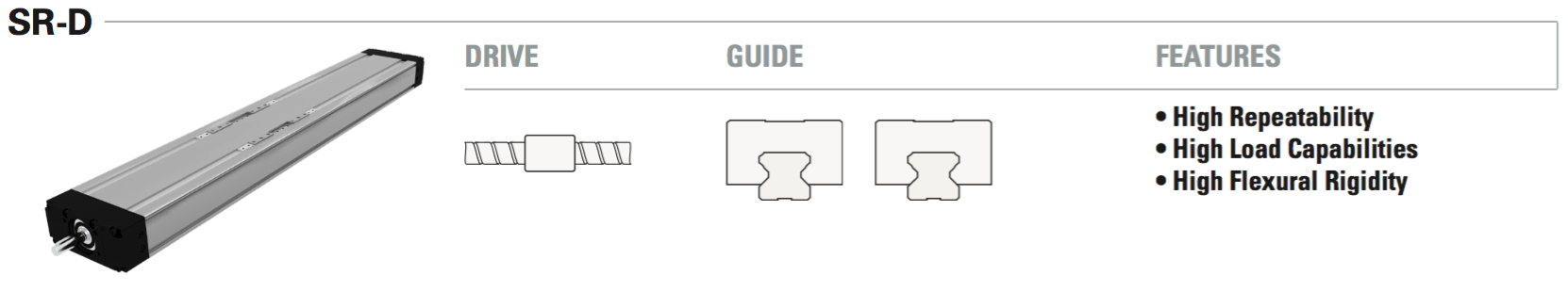

The SR-D series of linear units feature a precision ball screw drive and two parallel, integrated, zero-backlash rail guides. Compact dimensions allow high performance features such as, high speeds, good accuracy and repeatability and they can easily be combined into multi-axis systems. Two parallel circulating antistatic polyurethane sealing strips and an aluminum cover protect all the parts in the profile from dust and other contaminants.

Different carriage lengths with lubrication port allow for easy re-lubrication of the ball screw and ball rail guide system and allows the ability to attach additional accessories. The re-lubrication can also be done through maintenance holes on the side of the profile.

PC ELECTRIC CYLINDERS

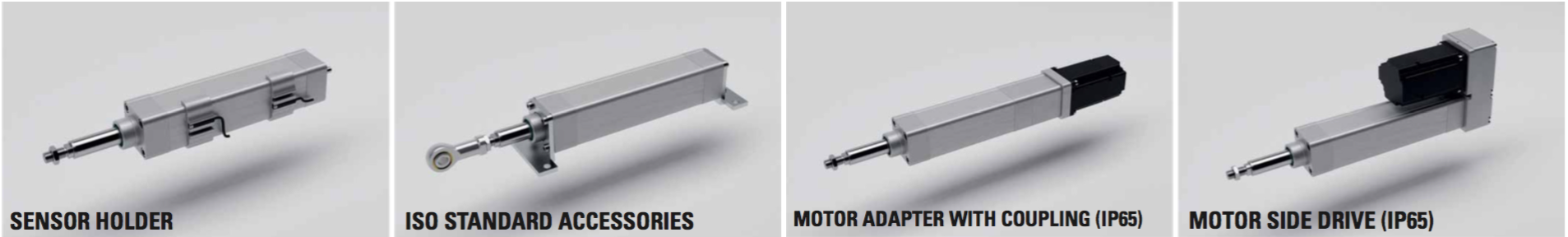

The WEISS PC Electric Cylinders with a precision ball screw drive are based on the standard ISO 15552. Its outer design and dimensions are very similar to pneumatic cylinders. High performance features such as, high speeds, good positioning accuracy and high repeatability are ensured through a precision ball screw with reduced backlash (preload on request) of the ball nut and non-rotating piston rod. For a long service life the re-lubrication can be done through a lubrication nipple.

The design‘s smooth surfaces enables easy cleaning of the cylinder. In combination with a class H1 lubricant, it is also suitable for food & beverage applications. It can be additionally equipped with switches and ISO standard accessories.

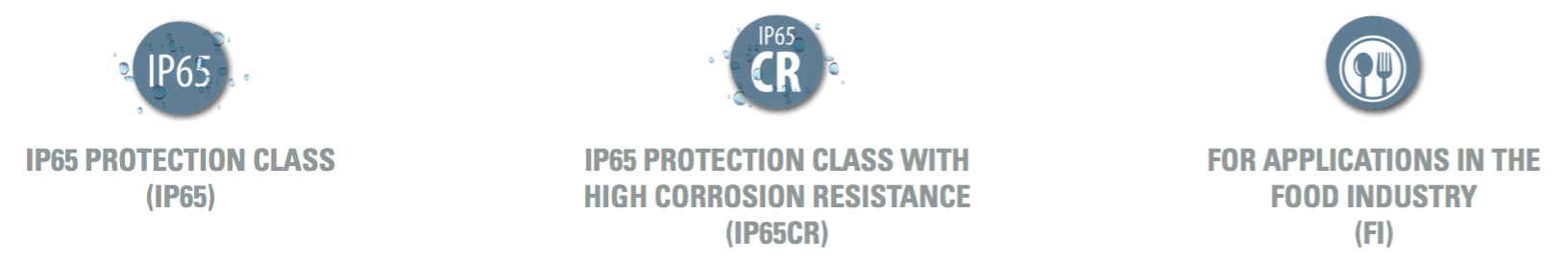

The excellent sealing of the components in the cylinder ensures an IP65 protection class and protects the interior of the cylinder from dust, water and other contaminants. Version IP65CR also offers high corrosion resistance in harsh environments.

About WEISS North America

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

Successfully competing in our increasingly competitive global environment requires strategy, innovation and proven reliability from a partner that you can trust. Give us a call at 888-WEISSNA or fill out the form above to schedule a call to discuss your automation needs.