WEISS BIW & Trunnion Solutions

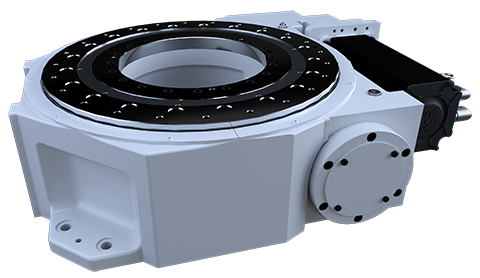

WEISS Body in White (BIW) & Trunnion Solutions are the ideal solution for robotic welding and positioning applications. Offering both single and multiple axis solutions, our trunnion and body in white solutions offer you the opportunity to fully customize and enhance your solution to meet your specific needs. Featuring the fastest index times in the industry, the reliable and robust WEISS CR rotary indexing table is the heart of each system.

Our decades of experience and leadership in mechatronics, process and supply chain management, along with world-class customer service and industry-specific expertise, have allowed us to grow and respond to all of our customers’ requirements. We are present and represented in all markets, precisely where our customers need us. WEISS North America is here to serve our customers as a one-stop-solution for automation in the United States, Canada and Mexico.

We invite you to learn more about WEISS BiW/Trunnion Solutions below.

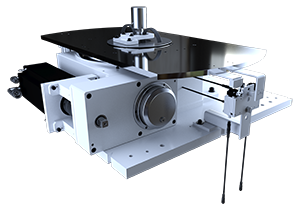

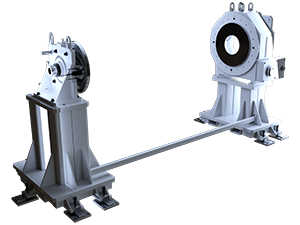

TRUNNION SOLUTIONS

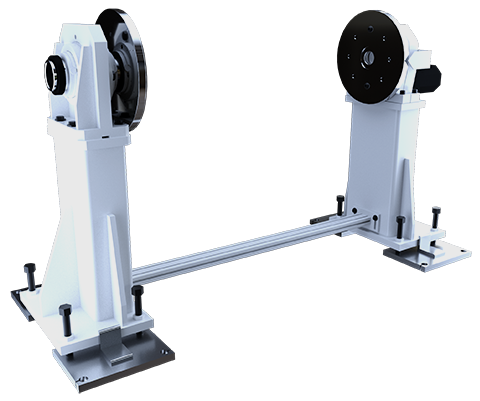

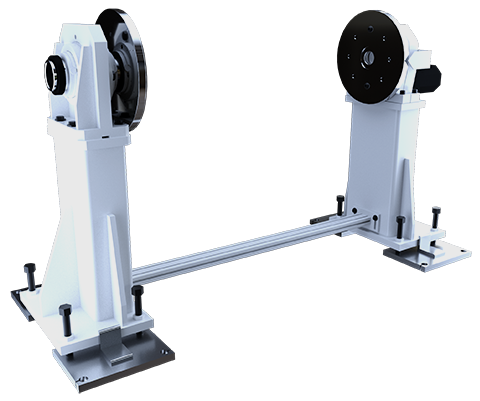

SINGLE HORIZONTAL AXIS – FREE STANDING

STANDARD FEATURES

- High Precision, low-backlash, “Planetary Plus” gearbox with hollow shaft

- WEISS installed and tested servo motor or interface kit for your preferred motor

- CW, CCW, and oscillating rotation

- Tailstock support with high radial load flange bearing, hollow shaft

- Integrated homing pin

- Overall height and span are customizable

- Customizable height and span

TH185 HORIZONTAL AXIS TRUNNION APPLICATION EXAMPLES |

||||

| Customer Payload (kg) | Span (mm) | Inertia (kgm2) | Time for 90° Move | E-stop Time |

| 500 | 2,500 | 55 | 1.35 | 0.2 |

| 1,200 | 3,000 | 200 | 1.35 | 0.3 |

| 2,000 | 4,000 | 350 | 1.50 | 0.4 |

The payload, span and inertia values include the part and tooling mounted between the headstock and tailstock. COG of tooling and part is located on rotation axis and centered between headstock and tailstock. Above examples are for 3000 RPM motor, 10 Nm motor torque and 20 Nm E-stop torque.

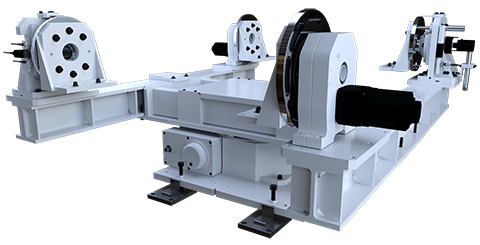

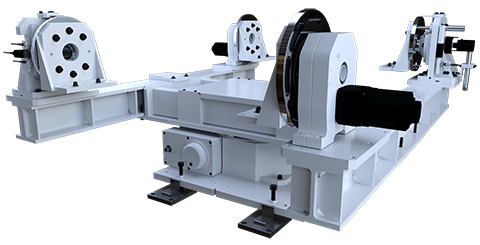

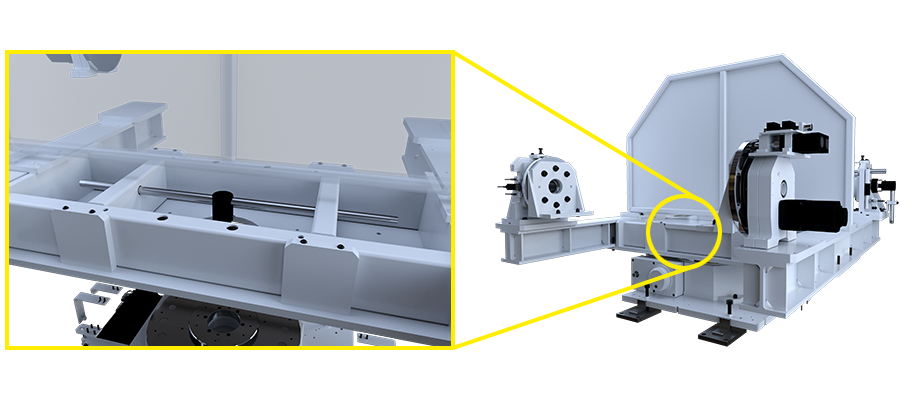

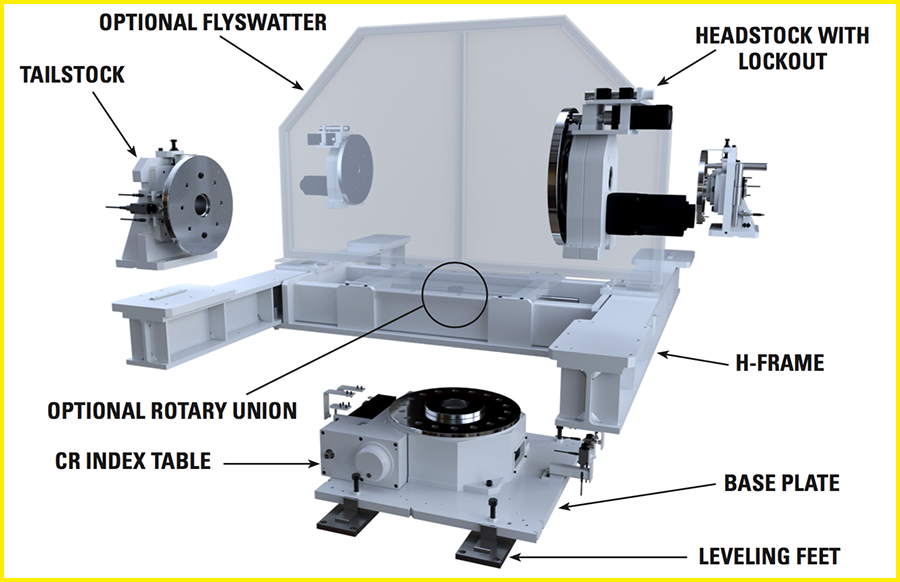

3 AXIS – H-FRAME

STANDARD FEATURES

- CR Series heavy duty freely programmable rotary indexing table used for vertical axis

- H-frame with a robust steel weldment

- Overall length and width are customizable

- Headstock and tailstock are same as above

- Quick E-stop times

VERTICAL AXIS TRUNNION APPLICATION EXAMPLES |

|||||

| Model | Customer Payload Per Side (kg) | Total Load (kg) | Inertia (kgm2) | Time for 180° Move | E-stop Time |

| CR700S | 500 | 3,000 | 4,000 | 3.5 | 0.5 |

| 800 | 3,600 | 5,000 | 4.1 | 0.5 | |

| CR700S | 1,200 | 5,200 | 9,500 | 4.1 | 0.5 |

| 2,000 | 7,000 | 15,000 | 5.5 | 0.5 | |

The total load and inertia include everything mounted to the vertical axis rotary table.

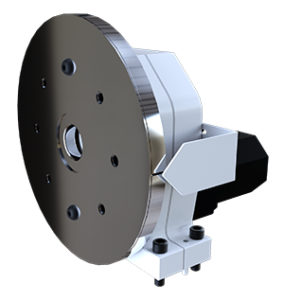

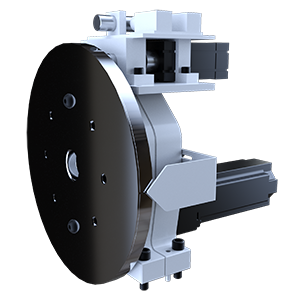

TRUNNION EXAMPLES AND OPTIONS

Additional features available to aid in positioning, locking, assembling equipment between headstock and tailstock. Our WEISS engineering team is ready to work with you on any application-specific customization required.

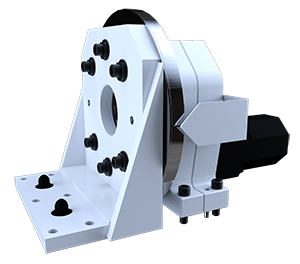

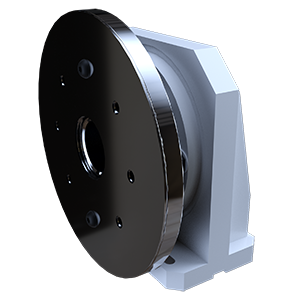

STANDARD HEADSTOCK

HEADSTOCK WITH LOCKOUT PIN

HEADSTOCK AND TAILSTOCK SHELF MOUNT

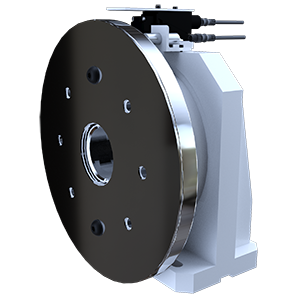

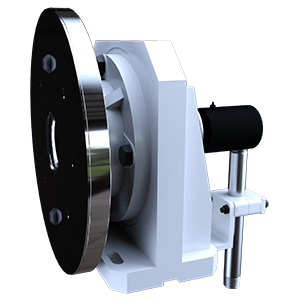

STANDARD TAILSTOCK

TAILSTOCK SWITCH KIT

TAILSTOCK ROTARY AIR UNION

H-FRAME WITH OPTIONAL ROTARY UNION

(INCLUDES PIPING TO END FOR EASY CONNECTION)

H-FRAME WITH OPTIONAL

WELD SPLASH GUARD/FLYSWATTER

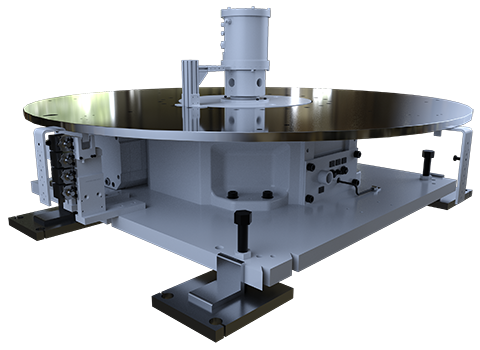

BIW SOLUTIONS

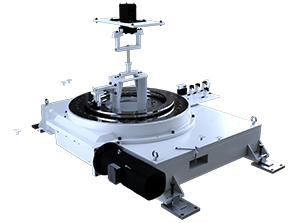

SINGLE VERTICAL AXIS

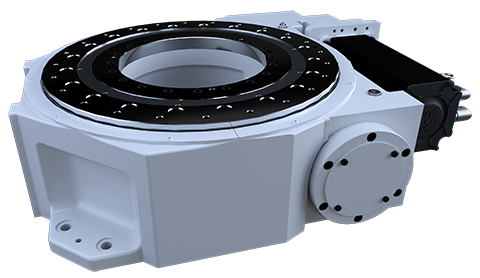

CR INDEX TABLE STANDARD FEATURES:

- Requires 15% less floor space per standard cell

- Fastest index times in the industry – more work time per station

- Fastest E-stop time in the industry – shorter walk time for operator optimizing weld time

- Integrated homing pin for easy table set up

- Large open center for cable management

- Low profile table

- No shot pin required for repeatability

BIW INDEX TABLE & PANEL DETAILS:

- Requires 15% less floor space per standard cell

- Fastest index times in the industry – more work time per station

- Fastest E-stop time in the industry – shorter walk time for operator optimizing weld time

- Integrated homing pin for easy table set up

- Large open center for cable management

- Low profile table

- No shot pin required for repeatability

BIW PANEL AND INDEXER VALIDATIONS:

- Motors pre-tuned to drive prior to shipment

- Drive is pre-loaded with motor data and tested

- On site Validations of the system available upon request – verify proper index time/e-stop time prior to shipment from builder

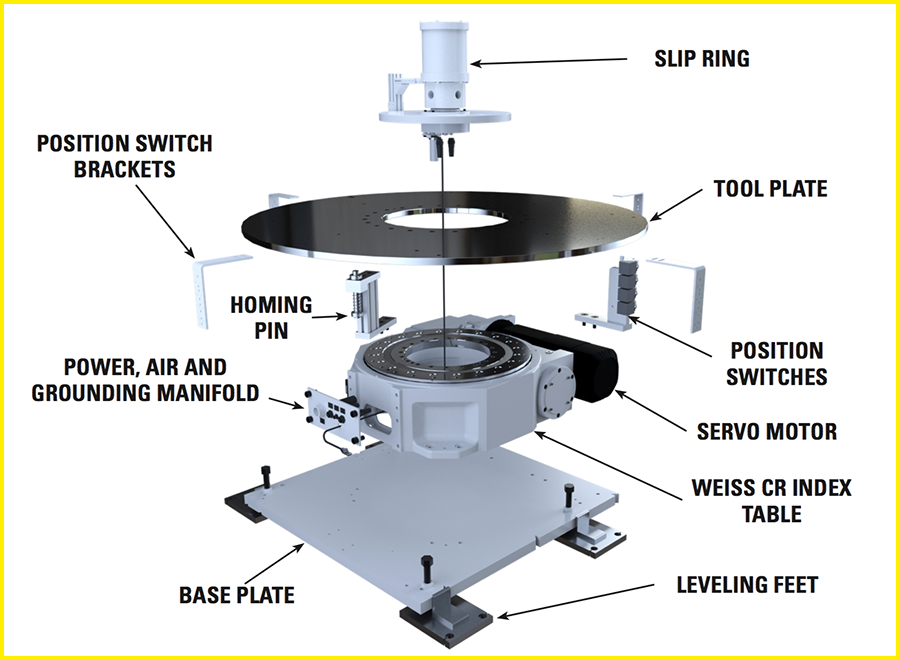

WEISS BIW PACKAGES:

- In position and over travel switches available

- Pre-designed cable management for air, power, communication and grounding cables

- Weiss slip ring available pre-wired to a manifold for convenient assembly

- Common base plate with certified leveling feet and anchors

- Top plate available with switches and brackets installed

- Complete system set up and run point to point for easy integration

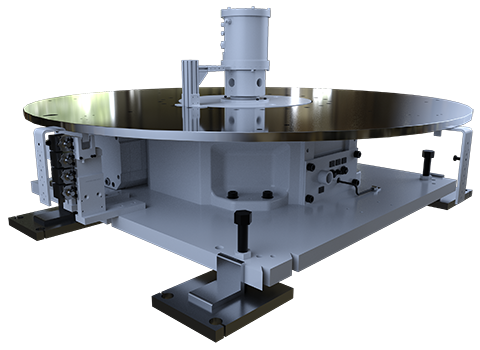

2-STATION BIW WITH TOOL PLATE

HEAVY DUTY BIW 4-STATION

HEAVY DUTY HORIZONTAL AXIS

EXPLODED H-FRAME ASSEMBLY

EXPLODED BIW 4-STATION ASSEMBLY

WEISS Rotary Indexing Overview Video

Each WEISS BIW & Trunnion System is equipped with a WEISS rotary indexing table. Here’s a brief overview of our fixed-station rotary tables, as well as our freely programmable rotary tables, to better acquaint you with the WEISS advantage. We also highlight some of our value-added products and services.

WEISS manufactures one of the most reliable and robust indexing tables available worldwide and we are a global leader in the field of automation. Extremely long service life combined with impressively fast switching technology is a characteristic of every indexing table we manufacture.

WEISS rotary indexing tables are maintenance free and offer the industry’s best warranty.

About WEISS North America

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

Successfully competing in our increasingly competitive global environment requires strategy, innovation and proven reliability from a partner that you can trust. Give us a call at 888-WEISSNA, fill out the form above, schedule a call below or simply send us an email to discuss your automation needs.